The report reveals that Apple has instructed managers to significantly cut the number of workers on iPhone assembly lines, aiming for a 50% reduction over the next few years. This directive came from Sabih Khan, Apple’s senior vice president of operations, following violent clashes between iPhone workers and police at Foxconn’s main assembly plant in November 2022.

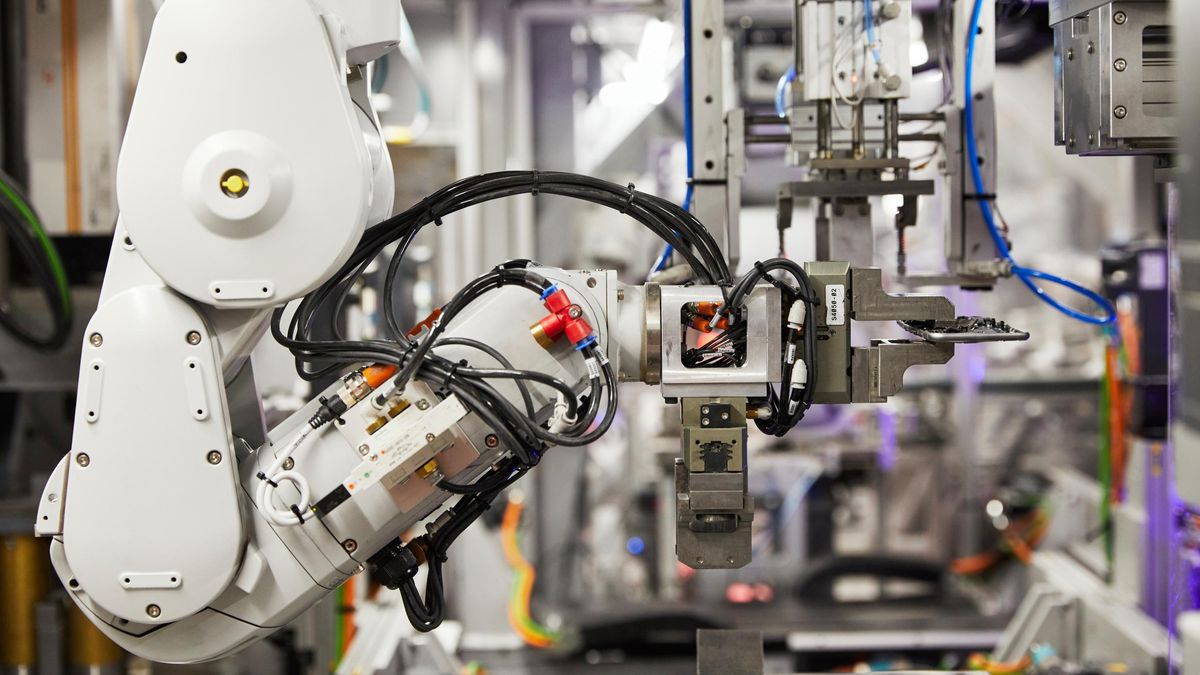

To achieve this, Apple is accelerating supply chain and production automation projects that were previously shelved due to high costs.

Automation machinery can cost hundreds of millions of dollars annually, and Apple has sometimes pushed its manufacturing partners to make these investments.

Apple’s annual supply chain reports show a decline in monitored employees for work-hour compliance, dropping from 1.6 million in 2022 to 1.4 million in 2023.

Significant automation is already in place for the iPhone 15 assembly, led by Peter Thompson, an operations vice president at Apple.

Thompson’s team has automated various assembly tasks, working with partners like Foxconn, Luxshare Precision, and Pegatron. These efforts have included the use of machines installing metal brackets, as well as flexible printed circuit boards without human intervention, reducing the need for thousands of workers in China.

Apple’s automation strategy has been bolstered by acquisitions, including DarwinAI and Drishti, which enables it to analyze video footage of assembly lines to identify bottlenecks and production issues in real time.

While Apple planned to automate the installation of iPhone buttons and other components for the iPhone 16, these plans were halted due to high defect rates.

Despite these challenges, Apple’s ultimate goal remains to cut the number of workers on final iPhone assembly lines by up to 50%.