Apple maintains a network of internal hardware labs dedicated to evaluating how devices respond to repeated pressure, temperature shifts and accidental drops. These labs operate throughout product development, allowing engineers to measure the strength of enclosures, the behavior of internal components and the reliability of assemblies across thousands of cycles. While much of this testing never appears in public product videos, internal procedures follow a consistent structure aimed at understanding how everyday wear affects long-term device performance.

The testing process begins with structural evaluations that analyze how a device reacts when subjected to bending, torsion and localized pressure. Engineers use precision equipment to apply controlled force to different areas of a device and monitor deformation across frames, display layers and internal supports. These measurements help identify stress points that may require reinforcement during the design process.

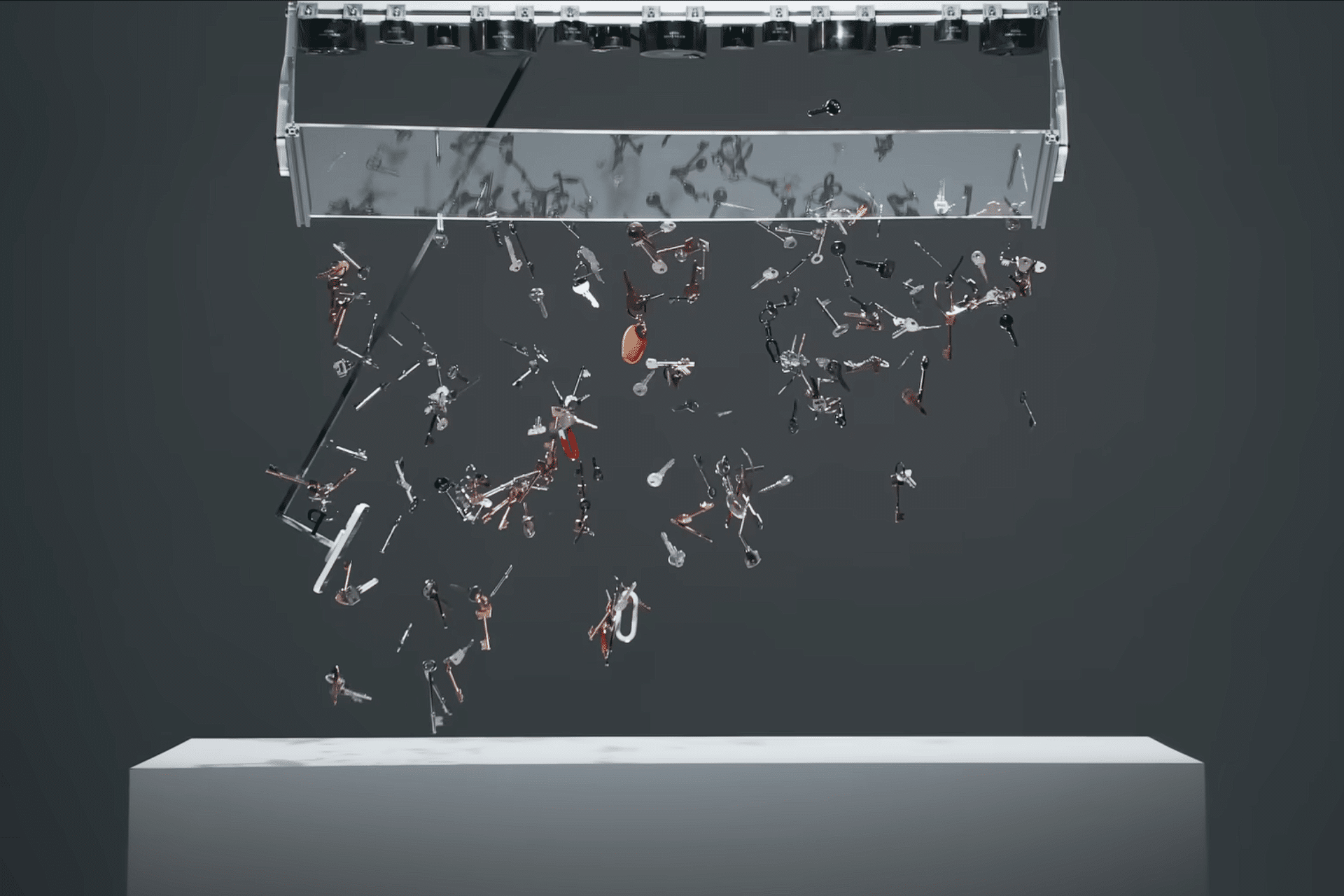

Drop and Impact Testing

Impact testing is one of Apple’s core durability procedures. Devices are released from predetermined heights onto surfaces engineered to simulate common real-world materials such as tile, hardwood and concrete. High-speed cameras record the moment of impact, while sensors track how force travels through the enclosure. Engineers use these readings to examine how glass, metal and adhesives behave under sudden load, comparing data across prototype iterations to evaluate improvements or regressions.

Environmental and Temperature Cycling

Apple also tests how devices handle extreme environmental changes. Environmental chambers expose prototypes to controlled humidity, heat and cold, replicating conditions ranging from dry indoor climates to high-temperature outdoor exposure. Devices move through repeated cycles that push materials to expand and contract, helping engineers evaluate seal integrity, battery stability and adhesive performance when subjected to prolonged environmental stress.

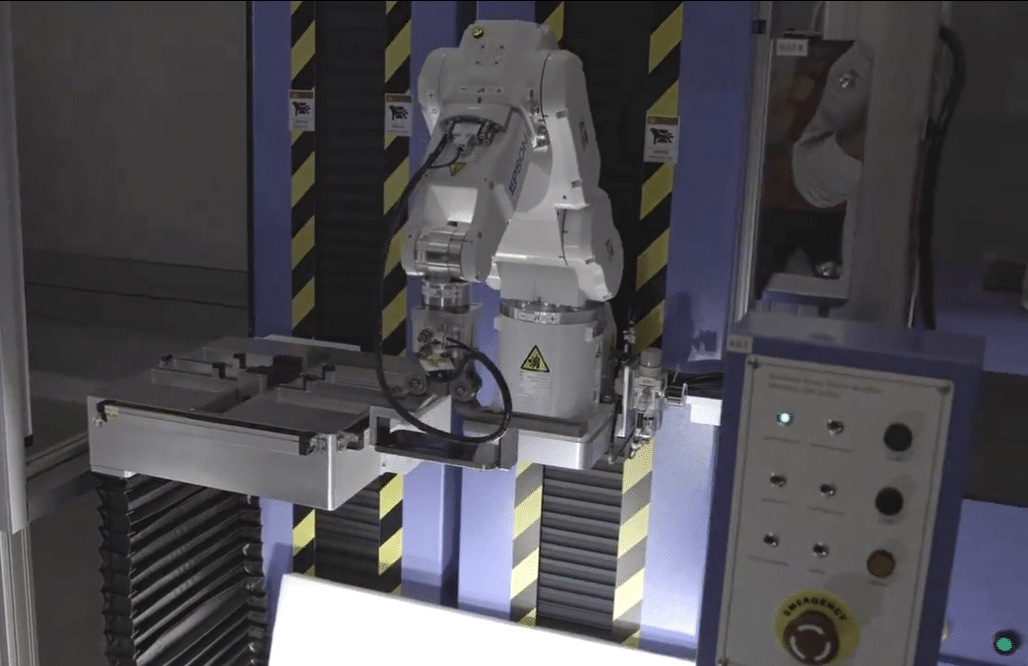

Mechanical Wear and Component Fatigue

To measure mechanical wear, Apple uses automated rigs that press buttons, toggle switches and insert or remove cables thousands of times. These machines apply repeatable force that simulates years of physical use within a condensed timeframe. Engineers record changes in button resistance, connector wear, and the consistency of electrical signals over the duration of testing. These findings guide adjustments to internal components and inform the selection of materials for moving parts.

Water and Dust Resistance Validation

Ingress testing is conducted through water-exposure cycles and dust-filled chambers designed to verify resistance ratings. Devices are placed under controlled water pressure, submerged at specific depths or exposed to fine particulates to check how seals and acoustic components behave under repeated stress. Engineers inspect devices after each cycle to confirm that gaskets, adhesives and structural joints maintain their integrity.

Thermal and Software-Linked Behavior

Thermal benches measure how heat generated during software workloads distributes across the device. Engineers run intensive tasks that push the CPU, GPU and neural engines to sustained output levels, collecting heat-mapping data to evaluate how internal layouts handle prolonged load. This testing influences component placement, cooling strategies and system-level power management decisions.

Daily Lab Workflow

Data gathered from impact events, stress cycles and environmental simulations flows into centralized engineering dashboards. Teams review results for patterns that highlight vulnerabilities or guide refinements to materials, structure or assembly methods. This continuous feedback loop links prototype revisions directly to lab outcomes, shaping how devices evolve throughout development stages.

Apple’s durability labs operate largely out of public view, but their testing processes play a central role in determining how devices withstand years of real-world handling. These procedures influence the structural architecture of products, refining everything from glass formulations to internal mounting systems to ensure consistent reliability across the company’s hardware lineup.