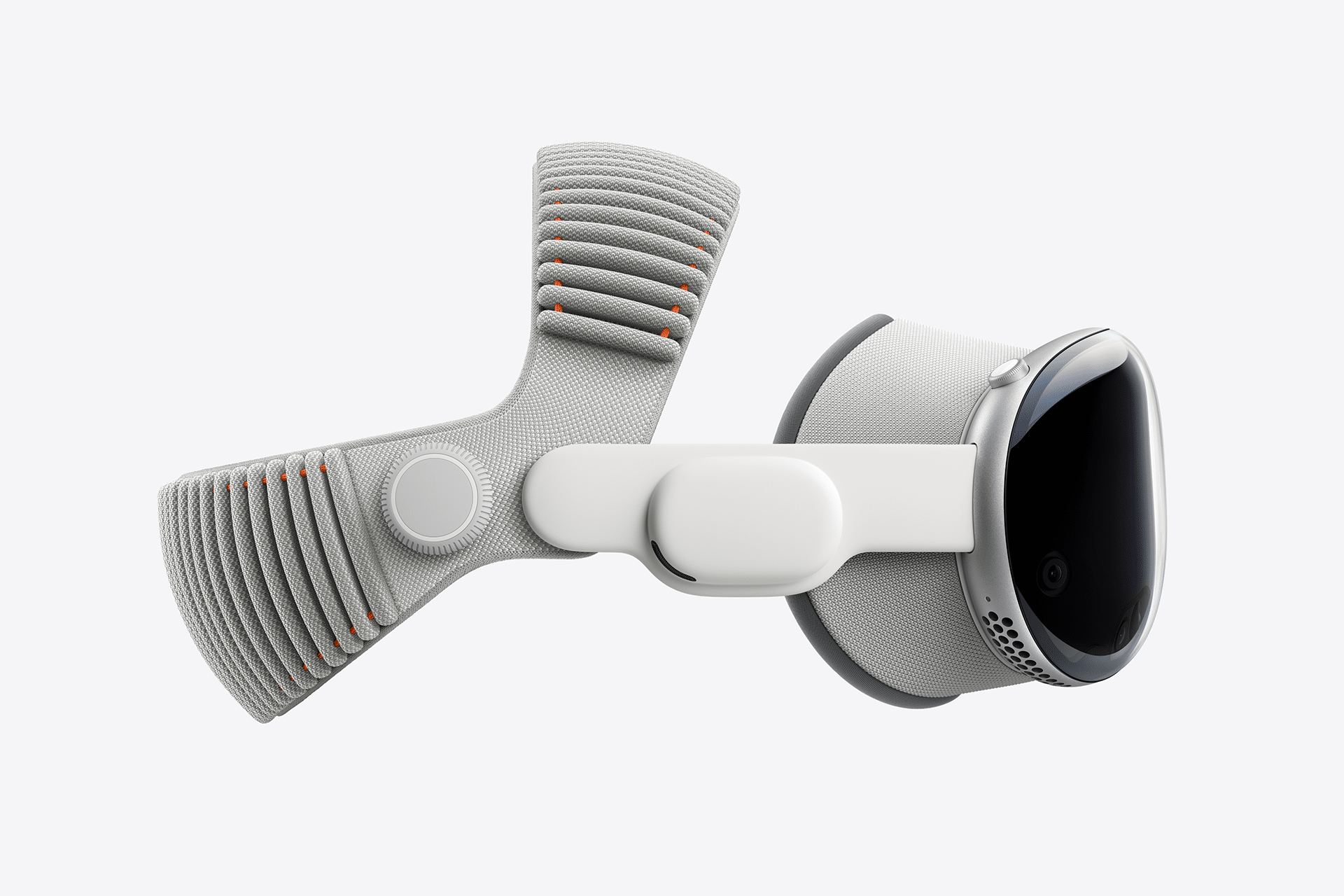

Apple has started producing its Vision Pro headset in Vietnam, marking one of the company’s most significant steps yet toward diversifying its global manufacturing base. The shift reflects Apple’s long-term strategy to reduce dependence on China for high-end product assembly while strengthening its foothold in Southeast Asia, a region that has rapidly become central to its supply chain.

According to people familiar with the matter, production in Vietnam began earlier this month, handled by Apple’s manufacturing partners who already produce components for AirPods and Apple Watch models. The decision to include the Vision Pro in the country’s manufacturing portfolio underscores the growing complexity and confidence of Vietnam’s electronics sector, which has evolved from assembling accessories to handling premium devices.

A Strategic Expansion Beyond China

For over a decade, China has served as the core of Apple’s manufacturing ecosystem, hosting a vast network of suppliers and specialized assembly lines for products like the iPhone, iPad, and MacBook. But mounting geopolitical tensions, pandemic-era disruptions, and shifting trade policies have accelerated Apple’s push to distribute its production capacity more evenly across Asia.

Vietnam has emerged as one of the primary beneficiaries of that shift. Its government has offered incentives to foreign tech companies, while local infrastructure investments have improved logistics and skilled labor availability. Apple’s expansion into Vietnam began with smaller accessories, gradually scaling up to major product lines — a process that now includes its most advanced mixed-reality device.

The inclusion of the Vision Pro is especially significant given the device’s complexity. As Apple’s most sophisticated wearable yet, it demands precision in optical assembly, sensor alignment, and microfabrication. Moving such production outside China signals growing trust in Vietnam’s manufacturing capabilities and Apple’s confidence in its partners’ ability to meet strict quality standards.

Supply Chain Diversification

The move aligns with a broader diversification trend across Apple’s portfolio. In recent years, iPhone production has partially expanded to India, MacBooks have been assembled in Thailand, and AirPods and Apple Watch models have been increasingly produced in Vietnam. Each step is part of a phased strategy to build regional redundancy, reducing risks from potential disruptions in any single market.

For Apple, the timing also coincides with the Vision Pro’s upcoming international rollout. After debuting in the United States earlier this year, the headset is expected to reach additional markets in 2026. Expanding production capacity to Vietnam could help support that expansion while maintaining tight control over output and logistics.

Manufacturing analysts note that Vietnam’s role in Apple’s ecosystem has matured from simple component assembly to handling core production of high-value products. This evolution mirrors the country’s broader transformation into one of Asia’s fastest-growing technology manufacturing hubs.

Producing the Vision Pro in Vietnam is not just a logistical adjustment — it reflects Apple’s intent to make the device more scalable and sustainable in cost terms.

The initial generation of the headset was produced in limited quantities, largely to refine manufacturing processes and gauge market demand. By shifting part of production to Vietnam, Apple positions itself to streamline costs as it prepares future iterations of the product.

The second-generation Vision Pro, already in early development, is expected to benefit from lessons learned in the transition. Vietnamese production facilities are reportedly working closely with Apple’s engineering teams to fine-tune assembly methods, including lens calibration, chip integration, and internal module alignment. This collaborative model is becoming standard for Apple’s global manufacturing strategy, in which multiple countries contribute specialized components to a single final product.

Quality and Precision

The move to Vietnam does not mean a compromise in quality. Apple has invested heavily in training, equipment, and local supplier development to ensure that production meets the same standards as its long-established Chinese facilities. Engineers from Apple’s main operations base have reportedly been working on-site to supervise early production runs and establish calibration benchmarks.

Vietnam’s manufacturing workforce, already experienced in producing smaller Apple devices, has adapted quickly to the Vision Pro’s more demanding processes. The country’s growing ecosystem of optical and electronic component suppliers also supports the shift, enabling faster iteration and shorter delivery cycles.

Apple rarely comments publicly on its manufacturing transitions, preferring to emphasize product design and innovation rather than production strategy. Yet every such shift marks an important evolution in how the company builds its ecosystem.

As the company looks toward 2026 and beyond, the Vision Pro’s expanding production network offers a blueprint for its broader hardware ambitions: highly advanced devices built across interconnected, globally distributed facilities.

Vietnam’s inclusion in that equation cements its role as one of Apple’s key partners in the next decade of device manufacturing.