Elon Musk has once again raised expectations for Tesla’s next major product category, claiming that the company’s upcoming Robotaxi/Cybercab vehicle will be produced at a speed “far beyond human capacities.” Speaking about the manufacturing concept, Musk described a factory process that functions more like a consumer electronics line than a traditional car assembly plant — capable of building vehicles in under five seconds per unit.

The comment underscores Tesla’s long-standing ambition to revolutionize automotive production through extreme automation and artificial intelligence. Musk has often characterized manufacturing itself as the ultimate product, and his latest remarks suggest that Tesla’s robotaxi program could become the company’s most automated and efficient production line yet.

Manufacturing at Machine Speed

Tesla’s robotaxi production concept envisions a new kind of factory — one that relies heavily on robotics, AI coordination, and modular vehicle architecture. Instead of sequential stations where humans and robots perform discrete steps, the line would operate continuously, with automated subsystems assembling major components in parallel before merging them into complete vehicles.

This “machine that builds the machine” philosophy has been central to Musk’s approach since the launch of the Model 3, but the robotaxi marks its most ambitious application to date. If realized, Tesla could reach production rates measured in seconds per vehicle rather than minutes, effectively collapsing the traditional boundaries of car manufacturing.

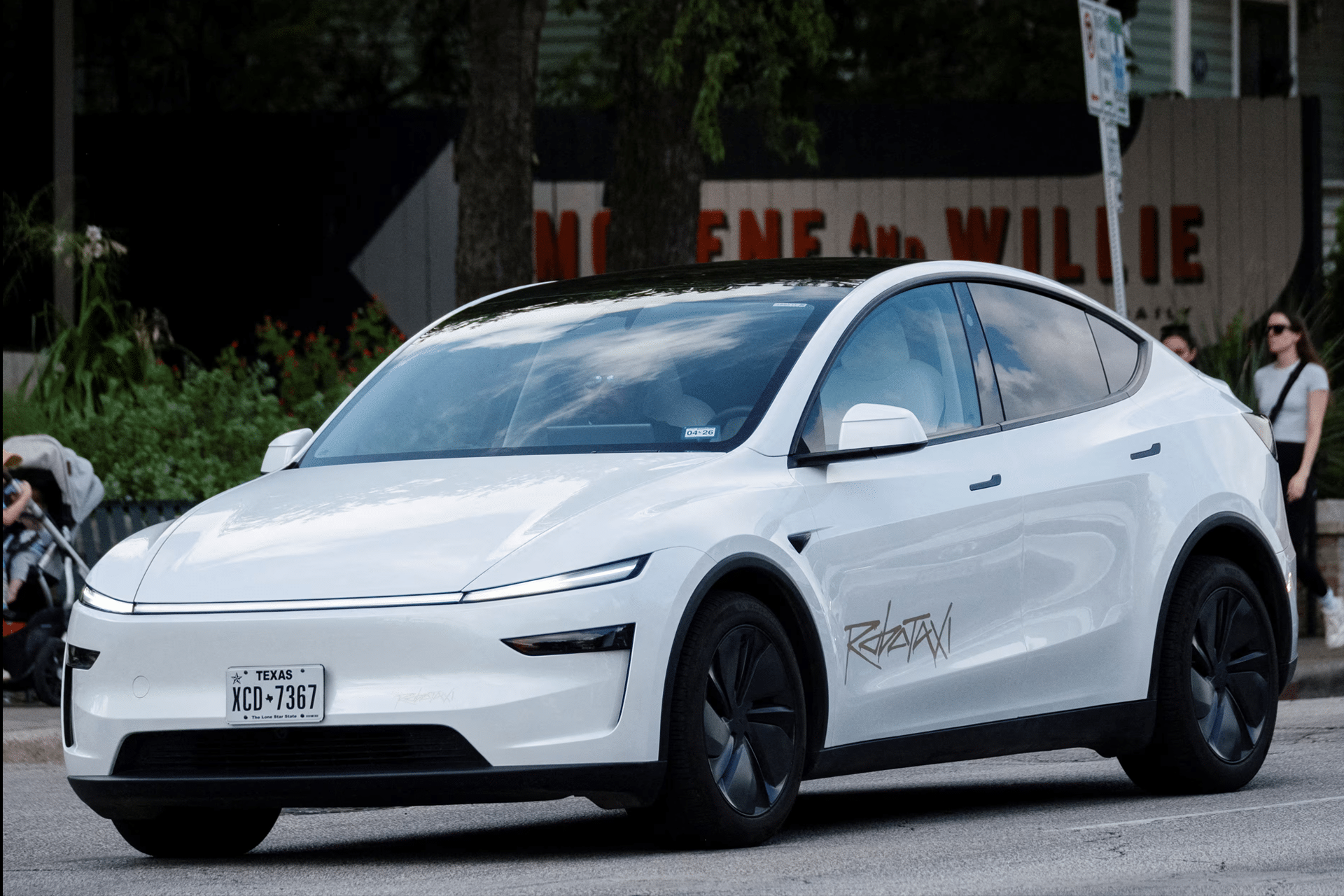

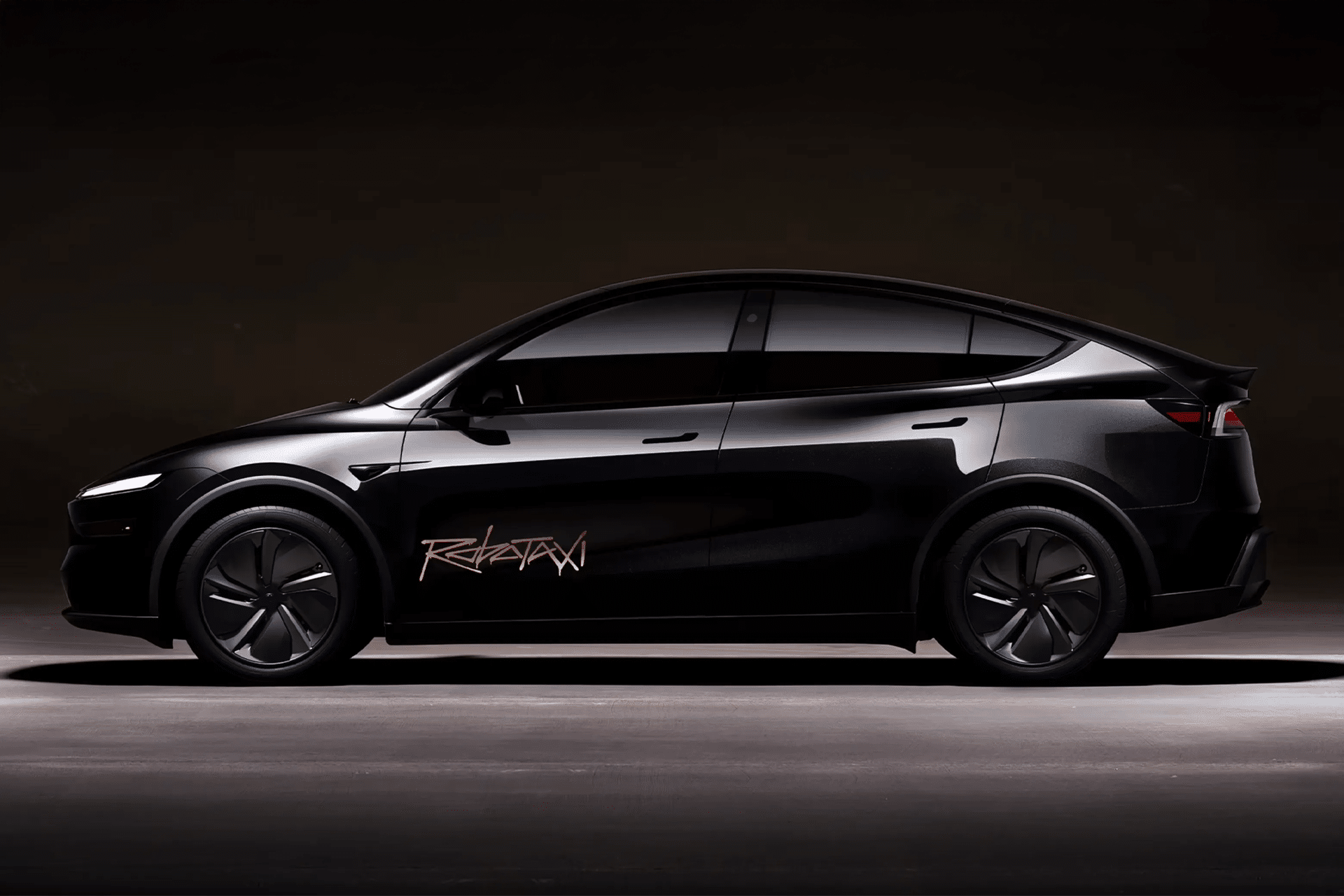

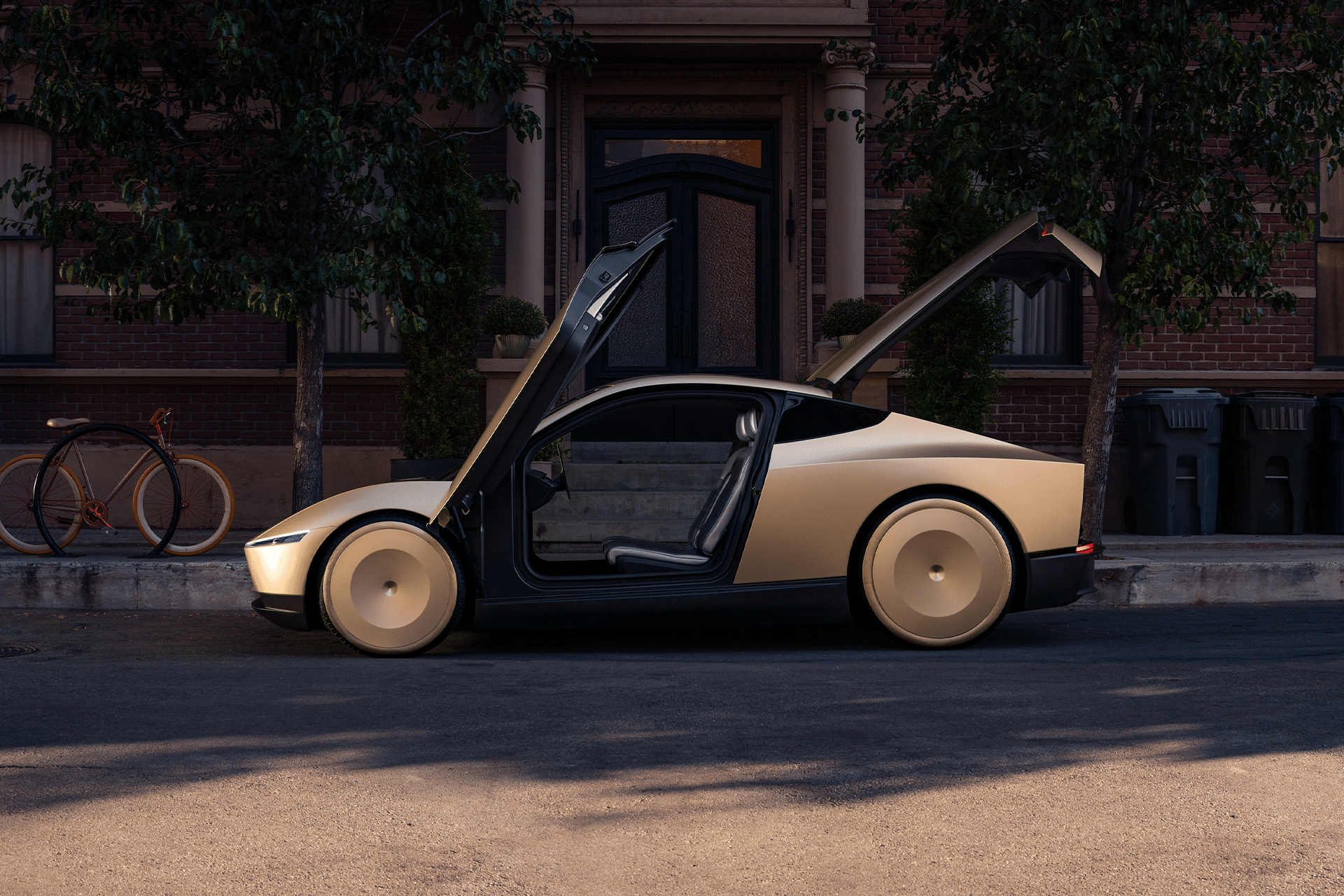

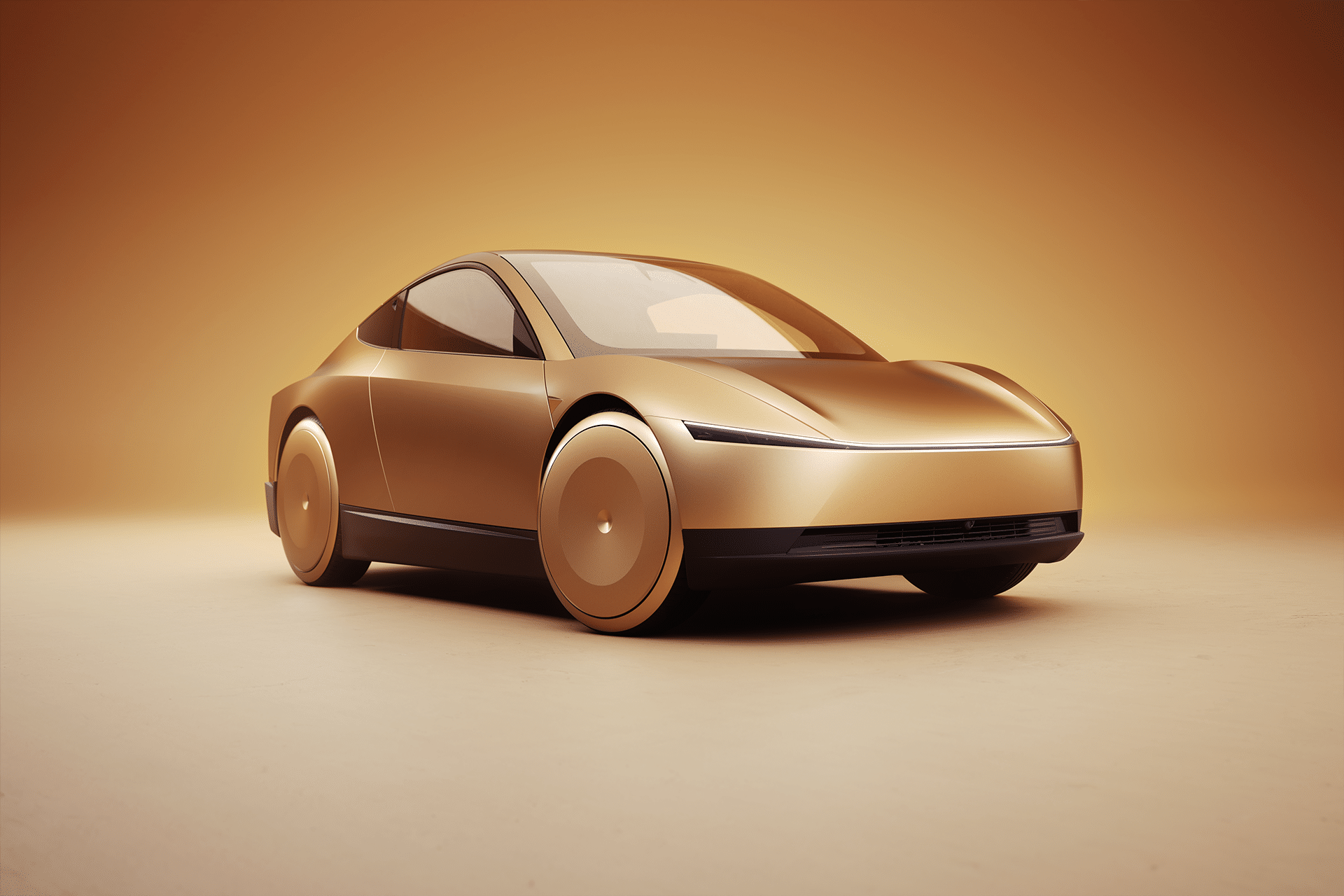

The Cybercab as Tesla’s Next Platform

Tesla’s first dedicated Robotaxi — referred to internally as the Cybercab — is expected to feature a fully autonomous driving system, minimal interior controls, and a chassis designed specifically for ride-sharing. The model will reportedly use next-generation structural battery packs and an optimized electric drivetrain to support continuous fleet operation.

By removing many of the human-centric components found in standard vehicles, such as steering mechanisms and manual controls, Tesla can simplify the manufacturing process while reducing weight and complexity. This architecture also allows greater flexibility for factory automation, since fewer manual assembly steps are required.

Tesla has been expanding its Gigafactory Texas operations in preparation for the Cybercab line, with new roles focused on robotics, precision tooling, and high-speed automation systems. The company’s goal is to create a facility that can scale production to millions of vehicles annually without relying heavily on manual labor.

A Vision of Fully Automated Manufacturing

Musk’s reference to production “beyond human capacities” reflects Tesla’s broader view that the future of manufacturing lies in self-improving systems. Using AI to manage everything from part logistics to assembly timing, Tesla envisions a process that can adjust itself in real time based on data from sensors and predictive models.

In this vision, the factory becomes an autonomous organism — constantly learning, optimizing, and correcting inefficiencies without human intervention. Musk has compared this model to semiconductor fabrication, where precision automation and tight feedback loops have driven exponential productivity gains.

Ambition Meets Reality

While the idea of sub-five-second vehicle production has captured attention, analysts remain cautious. Even with Tesla’s track record of manufacturing breakthroughs, scaling such a system involves significant technical and logistical challenges. Quality control, supply consistency, and software validation will all play crucial roles in determining whether the company can achieve the level of automation Musk describes.

Still, Tesla’s trajectory points clearly toward increasing autonomy in both vehicles and production. The robotaxi program represents the intersection of those two goals: cars that drive themselves, built by systems that operate largely without human oversight.

If Musk’s vision proves even partly accurate, the Cybercab could do more than expand Tesla’s lineup — it could redefine how machines build machines, setting a new global standard for industrial automation.