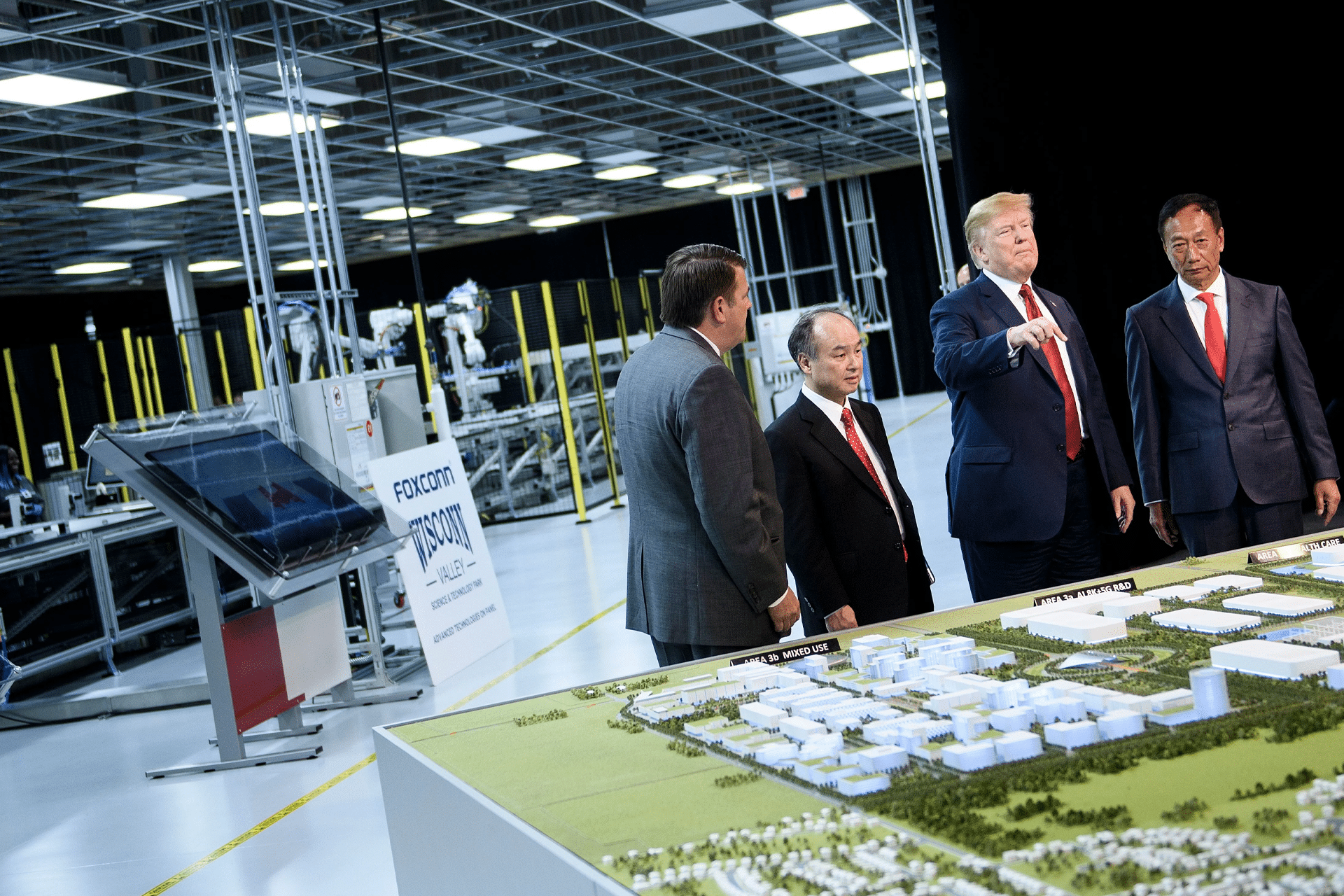

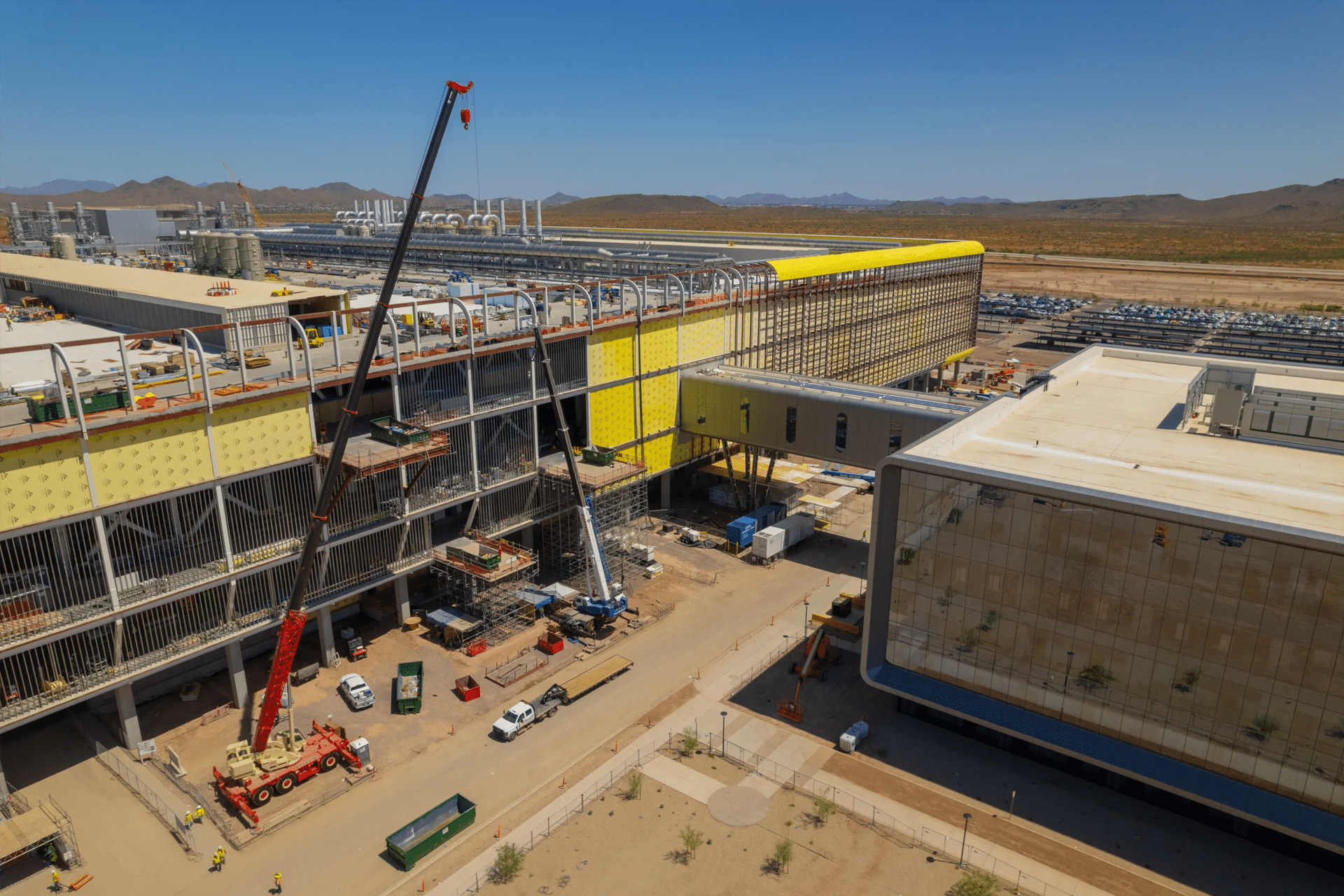

Foxconn is expanding its Mount Pleasant site with a $569 million investment aimed at supporting new manufacturing lines tied to AI-related hardware and advanced electronics assembly. The initiative broadens the company’s presence in Wisconsin after years of scaled-down plans, aligning the site with emerging production opportunities linked to OpenAI’s hardware ambitions. State economic officials and company representatives confirmed that the investment will upgrade facilities to handle more sophisticated manufacturing work and create additional high-skill roles in the region.

The expansion follows increased collaboration between Foxconn and OpenAI on hardware concepts requiring specialized assembly and precision manufacturing. People familiar with the plans say Mount Pleasant will support production for devices built around AI-integration requirements, though final product specifications have not been disclosed. The site’s upgrades include improvements to tooling, automation and quality-control systems designed to handle components used in next-generation computing hardware.

Why Foxconn Is Expanding in Wisconsin

The location offers proximity to major logistics corridors and access to a technical workforce suited for electronics assembly and advanced manufacturing roles.

US-based production supports supply-chain resilience for companies developing AI-centric devices, especially as demand rises for hardware optimized around large-model workloads.

Increasing collaboration with OpenAI creates opportunities for Foxconn to diversify beyond traditional consumer-electronics assembly into AI-device production and supporting components.

Officials said that recent assessments of the Mount Pleasant facility confirmed it has the scale to support multiple production lines once additional upgrades are complete. The new investment will be allocated to modernizing equipment, refining precision-assembly capabilities and improving energy-efficient infrastructure. These upgrades are intended to align the site with the requirements of AI-native devices and computing accessories expected to enter development pipelines over the next several years.

Regional and Industry Impact

The move represents one of the most significant updates to Foxconn’s Wisconsin presence since earlier large-scale plans were revised. State officials say the investment supports higher-value manufacturing than the company’s initial proposals and is more closely aligned with the evolving needs of the tech sector.

Industry analysts highlight that AI-hardware demand has created new opportunities for US-based assembly as companies seek geographically diversified production for sensitive or high-specification components.

Mount Pleasant’s expansion positions the region to participate in a supply chain increasingly focused on devices and modules designed for AI-enhanced computing.

Foxconn’s Wisconsin site has already supported smaller-scale electronics assembly and data-infrastructure projects. The new investment expands those capabilities significantly, with updates to robotics integration and precision-environment manufacturing. Early reports indicate that portions of the facility will be reconfigured to support iterative hardware development cycles, enabling rapid prototyping alongside production.

Alignment With OpenAI’s Hardware Direction

OpenAI’s hardware projects—developed in collaboration with design partners and contract manufacturers—require facilities capable of handling compact components, refined materials and advanced test procedures.

Foxconn’s updated Mount Pleasant operations are expected to support parts of this ecosystem, offering flexible assembly lines that can shift with evolving hardware concepts.

The collaboration allows OpenAI to leverage Foxconn’s manufacturing experience while enabling Foxconn to expand its role within AI-driven device development.

The manufacturing approach reflects a broader industry move toward distributing production across multiple regions to reduce risk. Analysts say OpenAI’s interest in US-based manufacturing aligns with that trend, and Foxconn’s expanded Wisconsin footprint positions it as one of the key suppliers capable of supporting such programs.

As Mount Pleasant’s upgrades progress, Foxconn will continue building out production capacity suited for AI-related devices, components and supporting electronics. The expansion reinforces Wisconsin’s role within emerging US technology supply chains and establishes the facility as a significant node for companies pursuing advanced hardware tied to AI development.