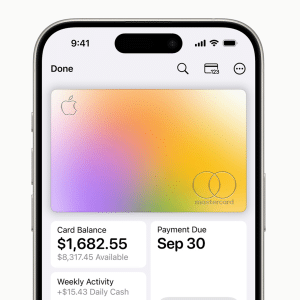

Foxconn, a key supplier for Apple, is facing unexpected difficulties in its Indian factories, primarily due to cultural differences, language barriers, and adaptation to demanding work schedules. This struggle is evident in the production of various iPhone models in India, a venture that began in 2019 with the iPhone XR and expanded to include flagship models.

Despite similarities in the physical setup of its Indian and Chinese factories, Foxconn’s transition to India has been far from smooth. A substantial report highlights the struggle of Chinese employees in adapting to the Indian work environment. They face language barriers, cultural shock, and challenges in implementing Chinese operational standards.

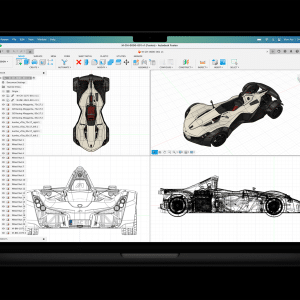

The factory machinery, sourced from China, features Mandarin instructions, creating significant communication hurdles. Employees often rely on translation apps and basic non-verbal cues, leading to frequent misunderstandings and disputes.

Indian labor laws, mandating eight-hour workdays with scheduled breaks, contrast sharply with the longer shifts common in China. Attempts by Foxconn to extend working hours in India met with resistance and failed to replicate the Chinese model of incentivizing longer work hours with extra pay. Indian workers have struggled with the rigorous schedules, leading to health issues and high stress levels.

Despite these challenges, there are signs of cross-cultural adaptation. Chinese employees appreciate the shorter working hours, and interactions between Indian and Chinese staff extend beyond work. However, the production output remains low, with less than 10% of iPhone 15 models being assembled at the Sunguvarchatram plant in India. More advanced models are still exclusively manufactured in China.

As Foxconn’s efforts to increase iPhone production in India continue, the report suggests that a blending of work cultures may be necessary.

While Apple and other companies benefit from lower labor costs in countries like India and China, transitioning away from Chinese production does not seem to alleviate broader supply-chain humanitarian concerns.