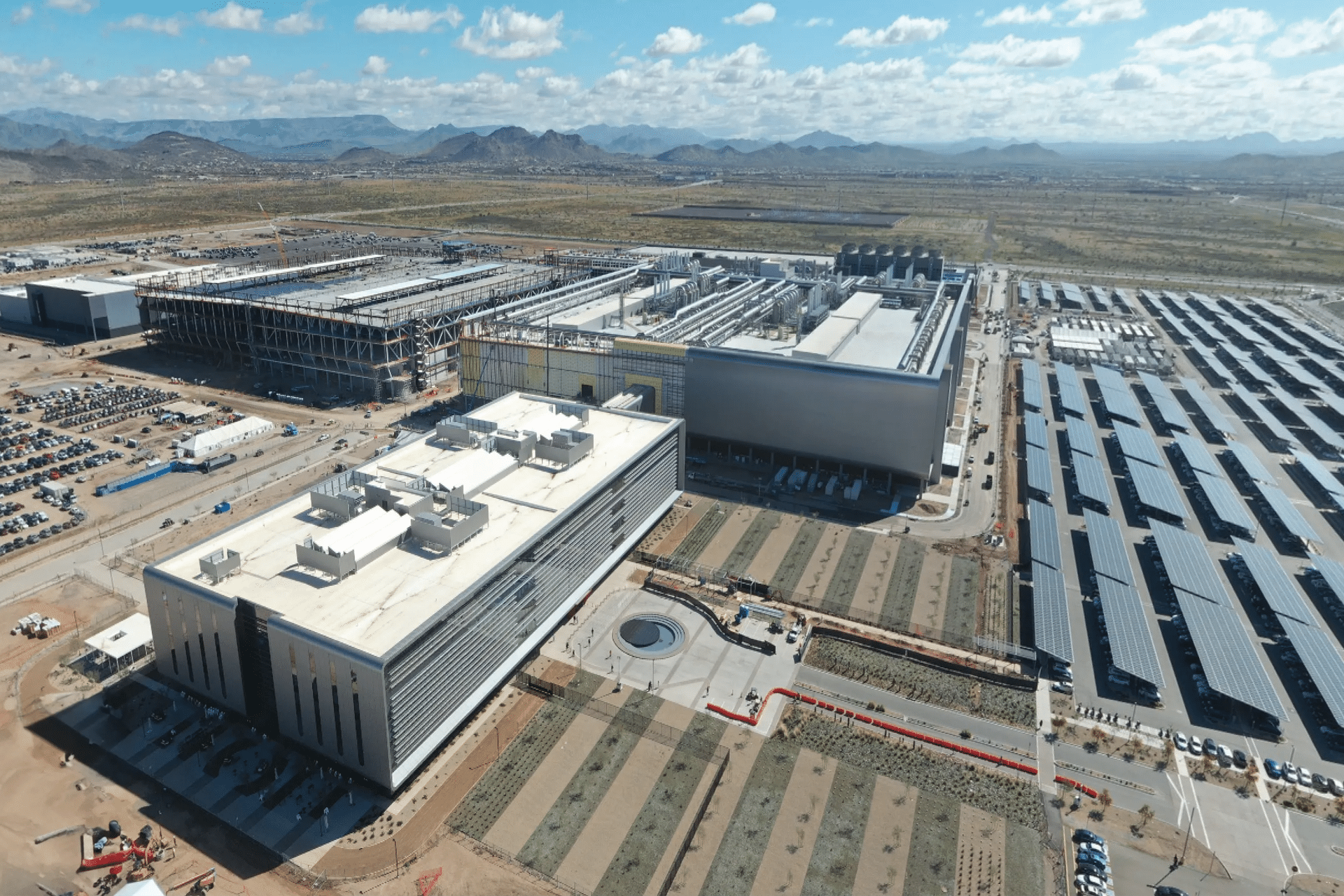

A BBC News tour showcased the Arizona facility’s clean rooms, where air purer than anywhere else protects the chipmaking process, as Faisal Islam noted. Wafers move via overhead rails across a “moat” accessed by a bridge, producing 14 trillion transistors per wafer for chips like the iPhone 15’s A16 Bionic, MacDailyNews reported. Apple’s Tim Cook championed the CHIPS Act, securing TSMC $6.6 billion in grants and up to $5 billion in loans, Reuters stated, enabling this high-tech hub.

Why It Impacts Tech Users

For Apple users, the TSMC Arizona chip plant 2025 means fewer delays for new devices. Past shortages stalled iPhone and Mac launches, frustrating fans. The factory, part of a $65 billion plan for three Arizona plants by 2030, produces 20,000 wafers monthly, Bloomberg reported. While only 1.6% of TSMC’s global output, it strengthens supply chains. By 2028, a second fab will make 2-nanometer chips for faster, energy-efficient devices like iPhones and AI wearables, TSMC confirmed.

Desert Challenges

Construction in Arizona’s desert faced hurdles. Delays pushed full production to 2025 from 2024 due to costs four to five times higher than Taiwan’s and a lack of skilled U.S. workers, Wikipedia noted. Half of the 2,000 jobs are filled by Taiwanese staff trained in Tainan, raising questions about the CHIPS Act’s job promises, 9to5Mac reported. Water usage, critical for chipmaking, consumes over 1 million gallons daily, though 90% will be recycled, CNBC stated. Phoenix’s semiconductor history with Intel and Motorola minimizes risks like earthquakes, Reddit users noted.

The Broader Impact

Apple’s partnership with TSMC, backed by Cook’s advocacy, makes the U.S. a growing chipmaking hub, countering risks from China-Taiwan tensions. However, most advanced 2-nanometer chips stay Taiwan-exclusive until 2028, with Arizona producing older tech like the A16 Bionic, Bloomberg noted. This ensures supply for legacy devices like AirPods but limits cutting-edge innovation to Taiwan. The TSMC Arizona chip plant 2025 creates 6,000 permanent and 20,000 temporary jobs, boosting Arizona’s economy, TSMC stated.

Future Outlook

With two more factories planned, TSMC’s Arizona commitment grows. Apple’s $500 billion U.S. manufacturing investment, including this plant, signals confidence in domestic tech, AZFamily reported. For users, this means reliable device availability. Challenges like water scarcity and labor gaps persist, Reddit forums discussed, but the TSMC Arizona chip plant 2025 sets a foundation for advanced U.S. chip production, strengthening Apple’s ecosystem.