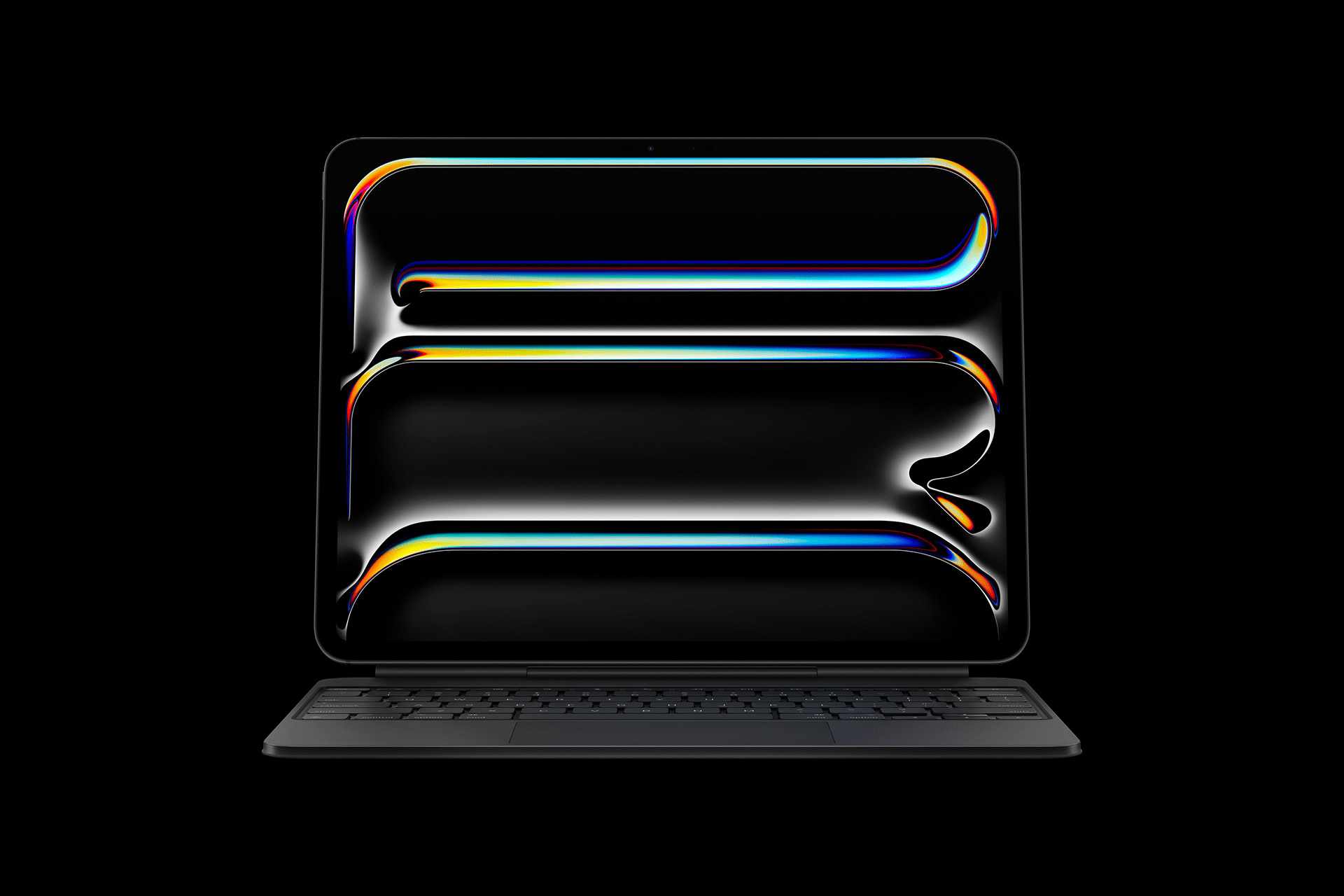

Apple’s next-generation iPad Pro could be the company’s first tablet to adopt vapor chamber cooling, a technology widely used in high-end laptops and smartphones to manage heat under sustained workloads. According to early reports from the supply chain, Apple is testing the new cooling system for the iPad Pro lineup expected in 2025, suggesting that thermal design is becoming increasingly critical as the M5 chip pushes performance boundaries inside the thinnest iPad ever made.

The addition of vapor chamber cooling would mark a notable engineering shift for the iPad, which has historically relied on passive aluminum dissipation. With each new generation, Apple’s custom silicon has delivered major power gains, but the physical limits of thermal diffusion in an ultra-slim chassis have begun to constrain sustained performance. The M5, with its AI-optimized cores and improved GPU architecture, likely demands a more advanced cooling method to fully realize its capabilities.

Performance Needs Driving Thermal Innovation

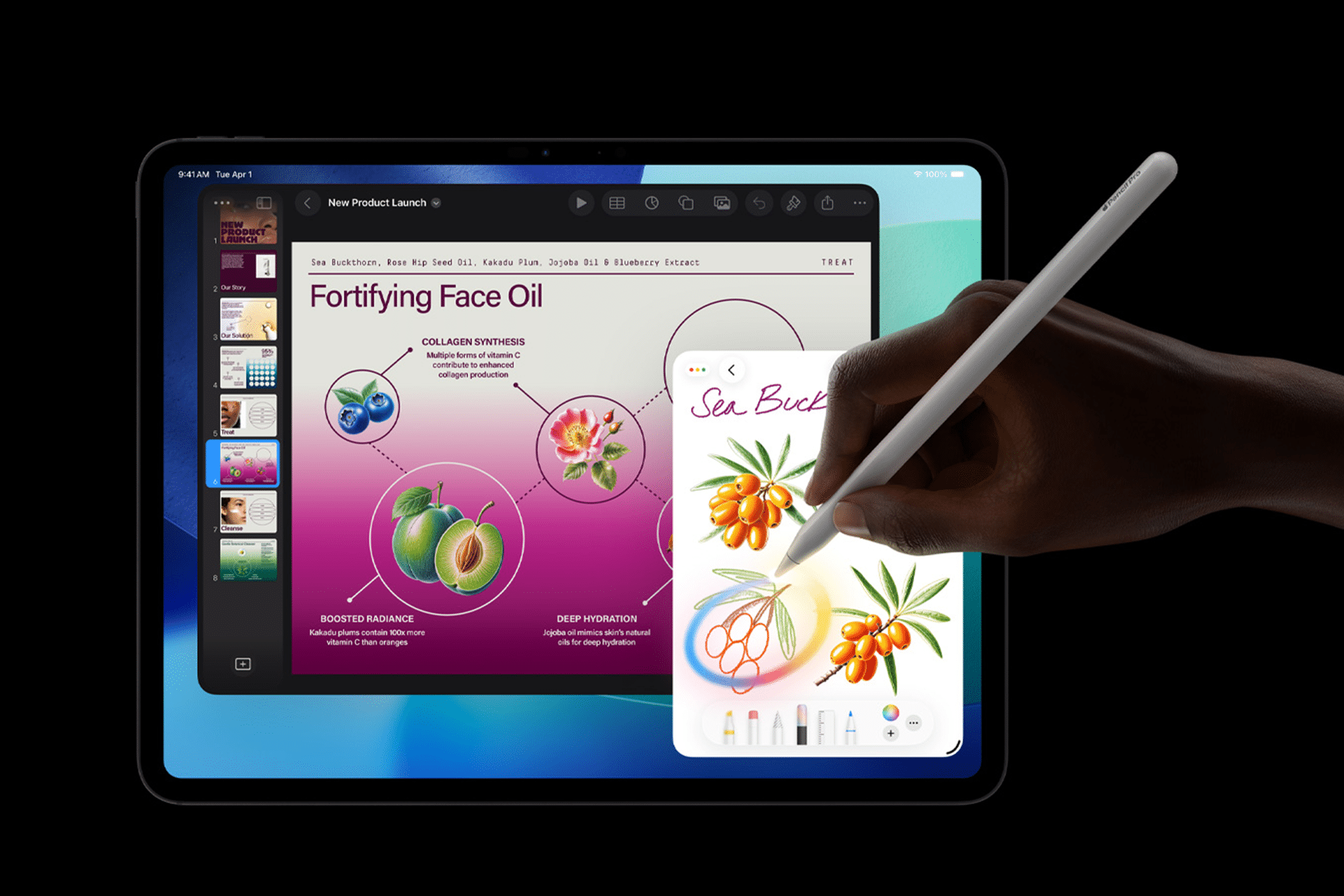

As the M5 chip bridges the gap between portable and desktop-class computing, heat management becomes a central concern. The iPad Pro’s fanless design, while central to its silent operation and slim profile, limits continuous high-performance output — particularly during extended creative or computational tasks like video rendering, AI-assisted design, or 3D modeling.

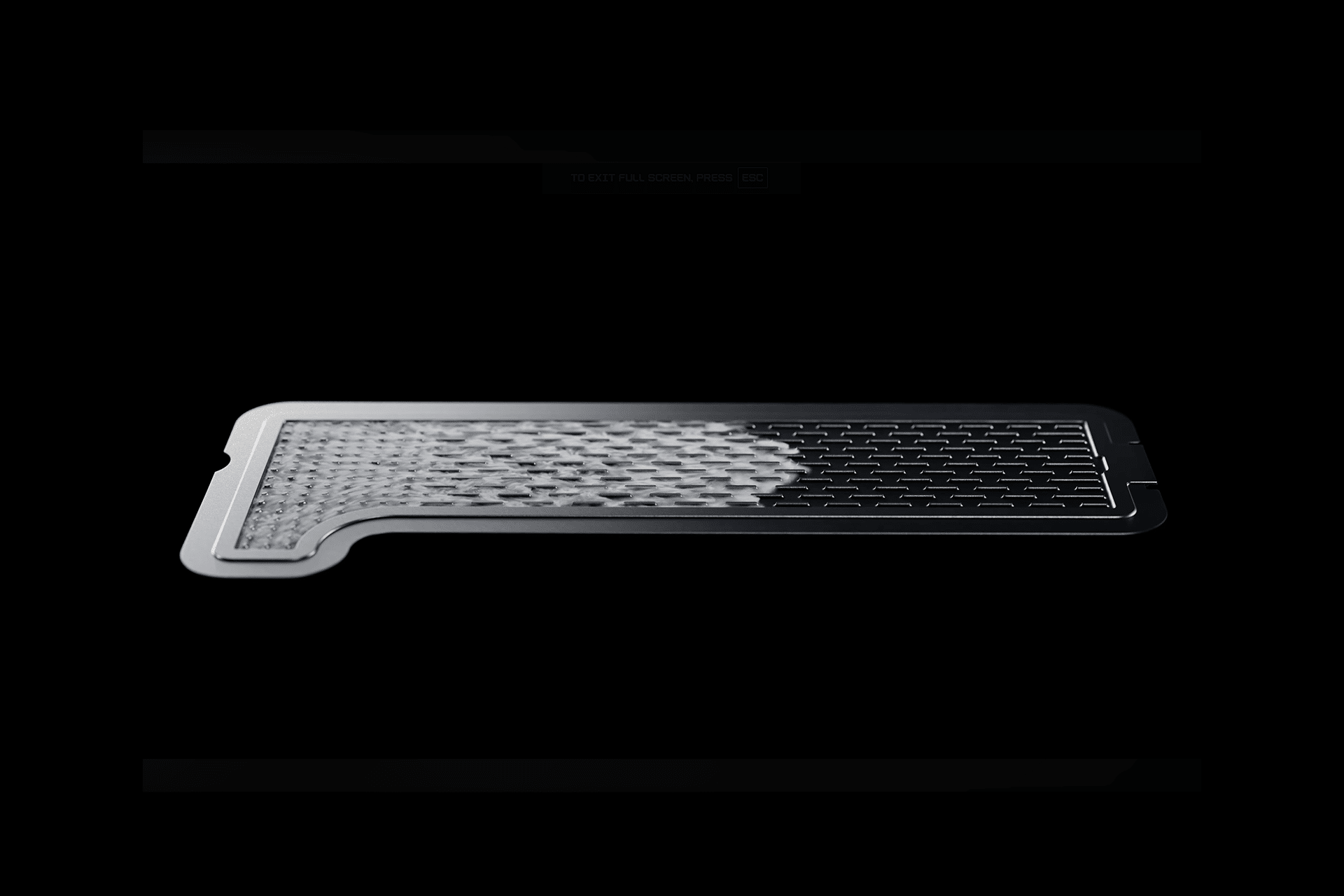

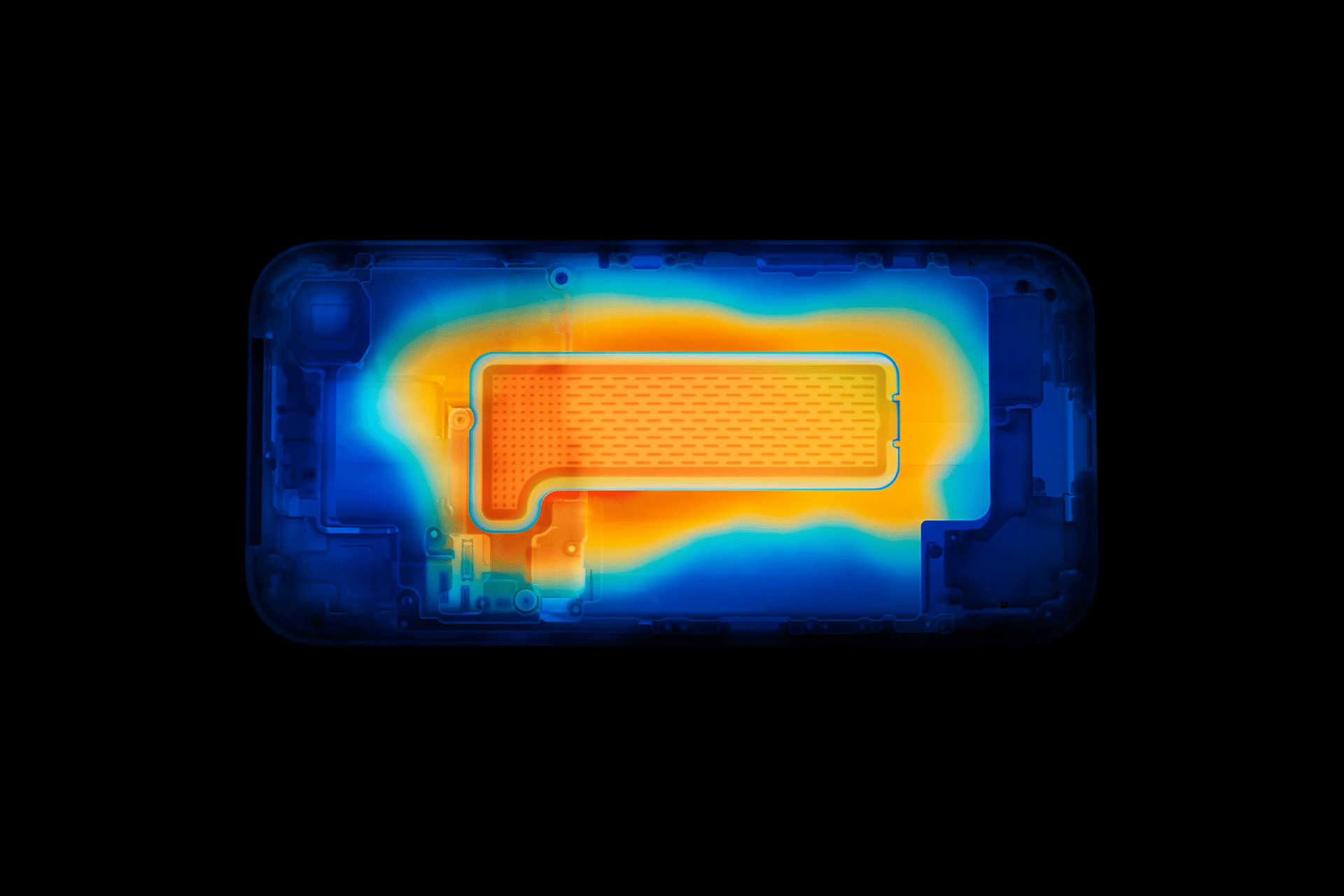

Vapor chamber cooling could solve that bottleneck. The system uses a sealed metal chamber filled with a small amount of liquid that vaporizes when heated. The vapor then condenses and circulates, distributing heat evenly across the surface and allowing the device to maintain higher speeds for longer durations.

In practice, this would mean fewer performance drops and cooler surface temperatures during intensive use. It could also extend the efficiency window of the M5’s neural engine and graphics cores, aligning with Apple’s broader emphasis on on-device AI processing.

A Continuation of Apple’s Thermal Design Evolution

The move toward vapor chamber cooling follows a gradual evolution of Apple’s approach to thermal management across its product line. The company first introduced advanced vapor chambers in its high-performance MacBook Pro and iPhone Pro models, where they enabled thinner builds without compromising sustained performance.

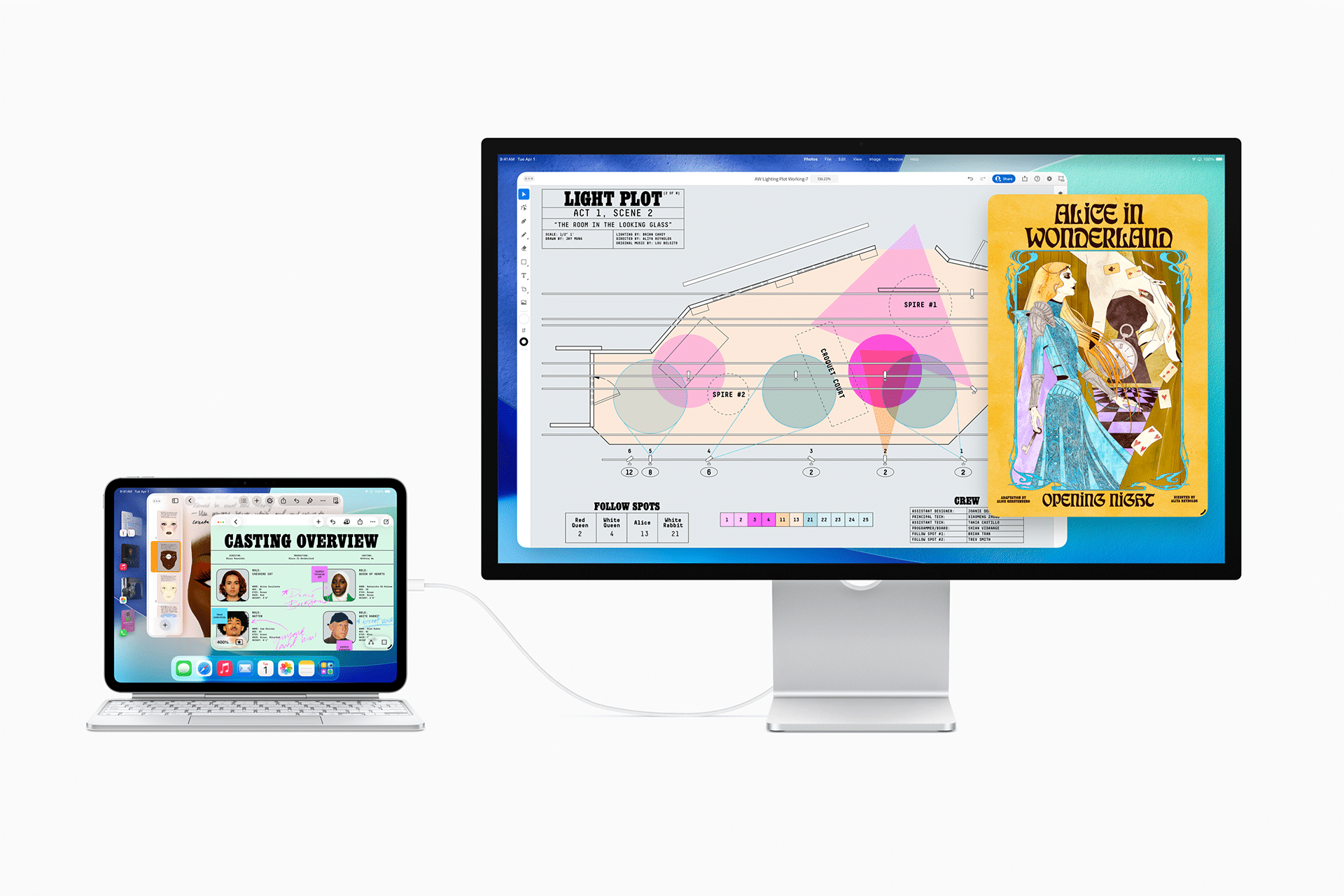

Bringing the technology to the iPad would represent the next step in Apple’s strategy to make its devices more consistent across categories — a trend accelerated by the unification of Apple Silicon. The M5 chip, shared among iPad, MacBook, and Vision Pro, makes it increasingly important for Apple to optimize thermals at every scale.

The new cooling system could also allow Apple to further refine the iPad’s industrial design. By improving efficiency, vapor chamber cooling enables thinner enclosures without overheating — a hallmark of Apple’s design language. With the current iPad Pro already the thinnest product the company has ever made, this innovation would ensure performance keeps pace with form.

Implications for Performance and AI

Beyond raw processing power, improved thermal headroom could play a pivotal role in Apple’s expanding on-device AIecosystem. As Apple Intelligence integrates into iPadOS, tasks like real-time translation, image generation, and semantic search demand constant background processing. These operations generate sustained heat, especially when combined with graphics-heavy workflows.

A vapor chamber would give the M5-powered iPad Pro more room to handle such workloads without throttling. Users editing 4K video, creating spatial content for Vision Pro, or running multiple AI-driven apps could see performance consistency approaching that of Apple’s active-cooled MacBooks.

Moreover, the new thermal architecture could pave the way for future iPad models featuring even more powerful chips or hybrid designs — potentially merging iPadOS and macOS functionalities in professional configurations. Apple’s hardware engineers appear to be designing with that scalability in mind, ensuring thermal stability for upcoming multi-tasking and AI-intensive workflows.

Balancing Silence, Efficiency, and Thinness

One of Apple’s greatest challenges is integrating advanced cooling while maintaining the silent, minimalist aesthetic that defines the iPad Pro. Vapor chambers, while compact, still require careful internal structuring to prevent warping and maintain durability under repeated heating cycles. Apple’s use of aerospace-grade aluminum and internal graphite sheets could complement this new system, creating a multi-layered heat dissipation structure without increasing device thickness.

Engineers are reportedly working on a redesigned internal layout to optimize space around the logic board and battery modules. This change could also improve the distribution of components, potentially enhancing the iPad’s balance and thermal isolation for user-facing surfaces.

The transition would mirror Apple’s broader commitment to sustainability. By improving energy efficiency and component lifespan, vapor chamber cooling supports Apple’s carbon reduction targets by lowering power draw and extending the operational life of each device.

Expected Rollout and Market Impact

While Apple has not officially confirmed the feature, industry sources point to late 2025 as a likely introduction window — coinciding with the next major iPad Pro refresh. The company is known for testing multiple prototypes before finalizing its designs, meaning vapor chamber cooling could debut first on higher-end configurations, such as the 13-inch iPad Pro, before reaching other models.

If implemented, the new system would strengthen Apple’s position in the professional tablet segment, where competition has grown with performance-oriented devices from Samsung and Microsoft. Vapor chamber cooling could give Apple an edge in sustained power delivery, allowing creative professionals to rely on the iPad for tasks traditionally reserved for laptops.

The development also reinforces Apple’s strategic focus on hardware convergence — narrowing the performance gap between iPad and MacBook. As chip capabilities increase and thermal constraints diminish, the distinction between mobile and desktop computing within Apple’s ecosystem continues to blur.

The introduction of vapor chamber cooling would mark another turning point in the iPad’s evolution, aligning with Apple’s ongoing mission to merge mobility with professional-grade capability. The M5 chip has already elevated the iPad’s potential; improved thermal management could finally unlock its full power across sustained workloads.

If the reports prove accurate, Apple’s next iPad Pro will represent more than just another performance boost — it will demonstrate how precision engineering continues to define the company’s identity. By solving one of the most fundamental challenges in mobile computing — heat — Apple could make its thinnest and quietest tablet yet its most capable one.