A Reddit post recently unveiled an image of a 3D printer bearing both xTool and Snapmaker logos, showcasing a four-head toolchanger capable of handling multiple materials in a single print. The prototype, spotted in a lab setting, appears to rival the capabilities of high-end models like the Prusa XL, which also uses a toolchanger for multi-material prints. With a build volume estimated at 270 x 268 x 270 mm, slightly larger than Bambu Lab’s X1C, and a print speed of 500 mm/s, the machine hints at a powerful contender designed for speed and flexibility.

The leak, traced to a French YouTuber and a WeChat conversation with an xTool engineer, suggests the printer runs on Klipper firmware, known for enabling rapid printing. While the details remain unconfirmed, the image shows four filament spools feeding the printer, indicating its ability to switch materials without manual intervention. This feature could appeal to hobbyists and professionals alike, eliminating the need to swap filaments mid-project and enabling complex, multi-color prints with ease.

xTool and Snapmaker: A Powerhouse Partnership

xTool, renowned for its laser cutters like the P2 CO2, is venturing into 3D printing with Snapmaker, a company celebrated for its modular devices that combine printing, laser engraving, and CNC carving. Snapmaker’s Artisan, launched in 2022, already impressed with dual nozzles, but this new collaboration takes versatility to another level. The four-head toolchanger allows users to load multiple materials—such as PLA, ABS, or TPU—simultaneously, streamlining workflows for intricate designs.

The partnership leverages xTool’s expertise in user-friendly hardware and Snapmaker’s experience with multifunctional systems. By combining forces, they aim to differentiate their offering from Bambu Lab’s H2D, a high-end printer that lacks an automatic toolchanger. The leaked prototype suggests a strategic move to capture the growing demand for multi-material printing, particularly among makers who value efficiency and creative freedom.

Bambu Lab’s Response to the Competition

Bambu Lab, a dominant player in desktop 3D printing, has been pushing boundaries with its H2D printer, boasting a 350 x 320 x 325 mm build volume and dual-nozzle extrusion. However, the absence of a toolchanger has sparked community discussions, with users on the Bambu Lab Community Forum requesting a multi-head system similar to the Prusa XL. Some propose integrating toolchangers with Bambu’s Automatic Material System (AMS), which could support up to 16 filaments, offering unparalleled material versatility.

Bambu Lab has faced scrutiny for recent moves, including a firmware update that limits compatibility with third-party software and PandaTouch screens, raising concerns about proprietary restrictions. Despite this, the company remains a favorite for its speed and precision, with the H2D capable of 1000 mm/s toolhead speeds. As competitors like xTool and Snapmaker innovate, Bambu may need to accelerate its development of a toolchanger-equipped model to maintain its edge.

Why Toolchangers Matter to Makers

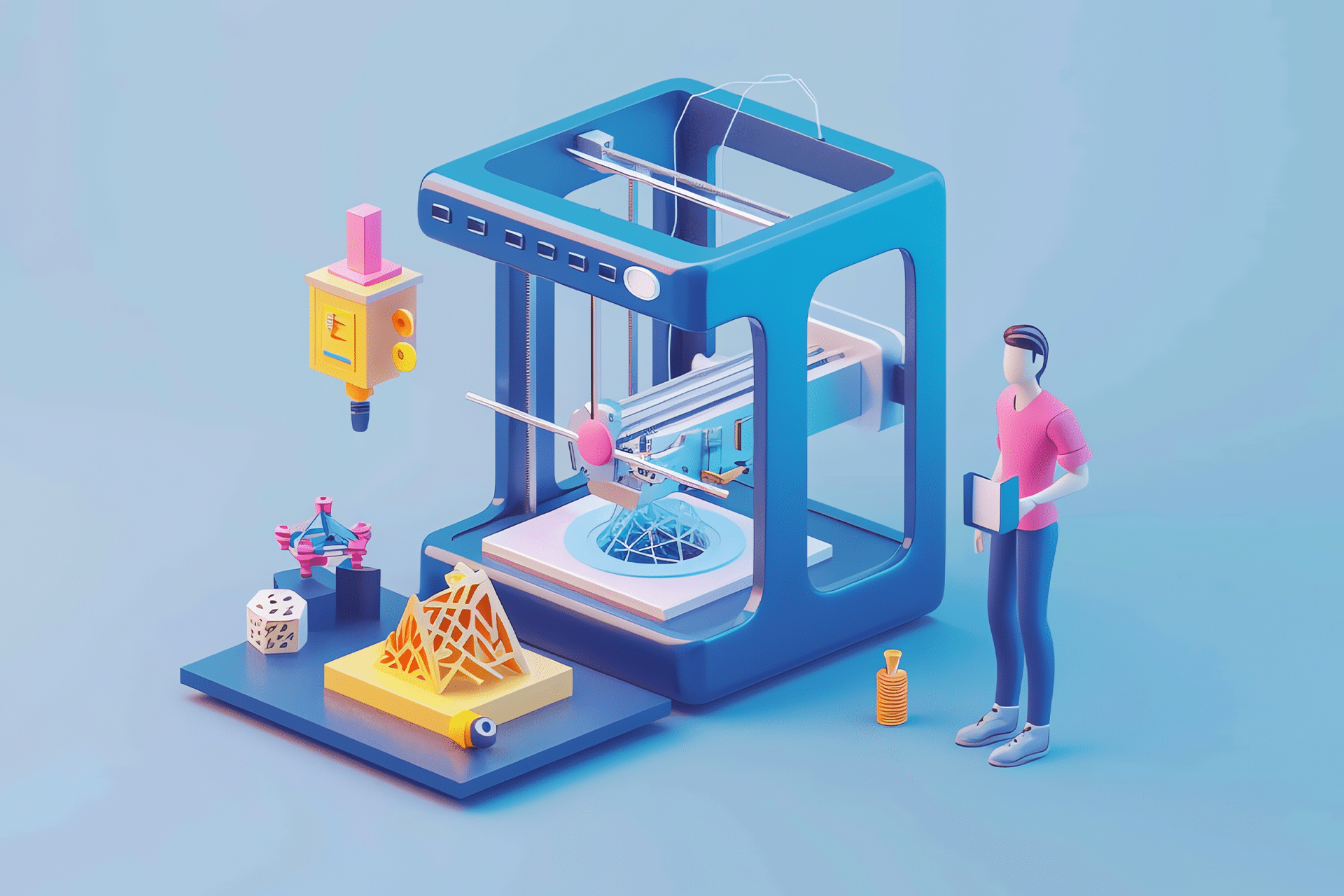

Toolchangers are a game-changer for 3D printing enthusiasts. By allowing printers to switch between multiple print heads, they enable seamless transitions between materials, colors, or nozzle sizes without pausing the print. This reduces waste, speeds up production, and opens the door to complex designs, such as multi-color models or parts with dissolvable supports. For small businesses and hobbyists, this means more efficient workflows and the ability to tackle professional-grade projects without investing in multiple machines.

The xTool-Snapmaker prototype, if launched, could democratize this technology. Unlike the Prusa XL, which carries a premium price and long backorder times, the new printer might offer a more accessible entry point. Its integration with user-friendly software, potentially based on Snapmaker’s Luban slicer, could further lower the learning curve, appealing to both novices and seasoned makers.

The Broader Impact on the 3D Printing Market

The emergence of toolchanger-equipped printers reflects a broader trend in the 3D printing industry: a race toward versatility and speed. Companies like Creality, with its K2 Pro, and Snapmaker, with its U1, are also innovating, but the xTool-Snapmaker collaboration stands out for its focus on multi-material printing. As Bambu Lab expands into laser cutting and xTool enters 3D printing, the lines between traditional manufacturing roles are blurring, creating a dynamic market where cross-disciplinary innovation thrives.

For consumers, this competition means more choices and potentially lower prices. The ability to print with multiple materials in a single job could expand applications, from custom prosthetics to intricate art pieces. However, challenges remain, including ensuring reliability in toolchanger mechanisms and addressing software compatibility, as seen in Bambu Lab’s recent controversies.

What’s Next for the Toolchanger Race

While the xTool-Snapmaker prototype is still unconfirmed, its leak has ignited excitement in the maker community. If it delivers on its promise of speed, versatility, and affordability, it could reshape the desktop 3D printing landscape. Meanwhile, Bambu Lab’s response—whether a new toolchanger model or enhancements to its AMS—will be critical in maintaining its market leadership.

As the industry evolves, the focus on toolchangers signals a shift toward printers that are not just tools but creative platforms. For makers, this means more freedom to experiment, innovate, and bring their ideas to life with fewer limitations. The race is on, and the winners will be those who can balance cutting-edge technology with user-friendly design.